|

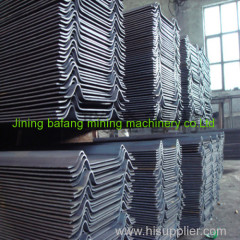

Shandong eight mining machinery co., LTD

|

injection pump and grouting pump

| Price: | 1.0 USD |

| Payment Terms: | T/T,WU |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Grouting pump adopts compressed oil or compressed air as power source, the use of oil cylinder or cylinder and cylinder has great effect of the grouti

Instruction

Grouting pump adopts compressed oil or compressed air as power source, the use of oil cylinder or cylinder and cylinder has great effect of the grouting area ratio, with smaller pressure can make the cylinder body produces high injection pressure.

Structure

Single cavity reciprocating pump working principle is shown in figure 1, when crank with angular velocity omega counterclockwise, the piston movement to the right, cavity suddenly increases, the volume of the cavity body liquid pressure is reduced, the outer pressure suction valve open and discharge valve closed, the liquid to be delivered under the action of pressure difference, to overcome the resistance of the suction people line and the suction valve and so on loss into the cavity. When the crank turns 180 ° after piston moving to the left, the liquid will be squeezed, liquid pressure in the body cavity has increased dramatically, in which a pressure under the action of suction valve is closed and the discharge valve is closed, the cavity fluids under the action of pressure difference is sent to the discharge line.Crank with angular velocity omega constantly rotates, reciprocating pump suction and discharge liquid.

Character

1, the pump structure is advanced, the rated output of high pressure, large displacement, high efficiency, easy to move, convenient in operation and maintenance;

2, full functions, which can be single-component slurry injection, can also be a two-component injection grout;Can be either chemical grout injection, also can cement and other slurry;Each cylinder synchronization work, mixing ratio can be adjusted, mixing evenly;And can serve as emulsion pump, hydraulic pump, etc., used for other occasions;

3, good safety, larger changes in the inflammable, explosive, temperature, humidity, are safe to use;

4. According to the different needs of customers to adjust parameters.Meet different pressure, flow rate and the special requirements of different transmission media;

5, can be three cylinder or two cylinder work, realize the request of 4:1 or slurry mixing ratio of 1:1, the pump pressure is high, the output flow is big, can meet high strength injection.